SEMI-AUTO STCRI STC-250

The smartest way to process multi-conductor cables!

This next-generation strip crimper is compatible with existing JAM-type applicators (with optional support for genuine applicators).

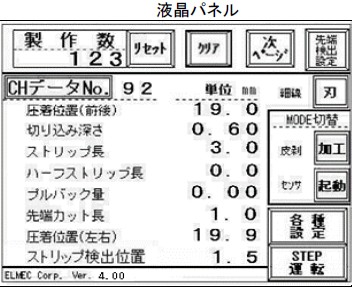

Unlike conventional models, where peel length adjustment was a limitation, this model features servo-controlled peel length adjustment, enabling precise settings via numerical input on a touch-screen LCD panel.

In addition, tip cut length, crimping position, and cutting depth are all numerically controlled for improved accuracy and consistency.

Features

● Easy setup of processing conditions

With servo control and an LCD panel, the crimping position of the wire and terminal, cut depth, strip length, half-strip length, pull-back amount, and tip cut length can all be set with one touch.

● Three selectable functions

Strip & crimp, strip only, or crimp only can be easily selected.

● Up to 100 processing conditions can be stored

Registered channels save processing conditions, significantly reducing setup time for the next operation.

● Short wire protrusion length

Enables processing with short wire protrusion lengths, suitable for cabtire cables and similar wires.

● Adoption of wire sinking during crimping

Since the wire sinks during crimping, wire bending is minimized.

● Easy applicator replacement

A one-touch base allows quick and easy applicator replacement.

J.A.M standard side-feed / end-feed applicators can be used (AS40, AS42, AE30).

With an optional conversion kit, genuine applicators from other manufacturers can also be installed.

● Equipped with Elmec crimping machine EIC-25

Allows easy height adjustment; features low noise, low vibration, energy saving, and lightweight design.

● Stripping functions

Semi-strip, tip cut, and offset pull (D-grip) can be easily set.

● Waterproof seal crimping function

The seal is positioned by blades, then stripped and crimped.

● Strip error detection function (optional)

Detects conductor breakage and improper stripping or crimping.

Process Sample

Specification

| Model | STC-250 |

| Crimping |

19,600N (equivalent to 2 tons) |

| Stroke Length |

30mm |

| Wire Size |

0.01~2.08mm2 (AWG#36~14) (Use a dedicated blade for #30 and above) |

| Tip Cut Length |

0~5.0mm |

| Processing Tact Time |

1.3 seconds/piece (varies depending on work) |

| Power Supply |

AC100V (50/60HZ) Single Phase |

| Compressed Air |

0.5MPa, approx. 6NL/time (strip dust collector) *Please use clean, dry air. |

| Machine Dimensions |

550W x 550D x 600H (mm) 115kg |

| Standard Accessories |

Reel Stand, Foot Switch, Power Cord, One-touch Base, Adapter |